„Reliable Filtration“ is HOBRA’s comprehensive mark under which all the company’s products and services in liquid filtration are identified. It is a marketing project which covers everything HOBRA manufactures, offers and supplies in this sphere.

Reliable filtration

- Applications

- Wine

- Beer

- Alcoholic beverages

- Soft drinks

- Food

- Chemistry

- Pharmacy

- Oil and biofuel

- Instructions - Filtration

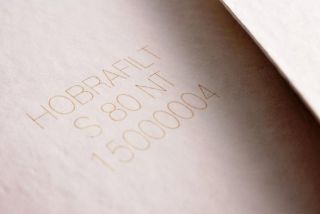

- HOBRAFILT „N“ and „NT“ Series

- HOBRAFILT - instructions with differential pressure specification

- ORBIFILT

- CANDEFILT

Hobrafilt

„NT“ Series

Hobrafilt® depth filter sheets are made of carefully selected and inspected materials, namely from various types of cellulose, high quality kieselguhr, perlites and specially treated resins. Filter sheet is in principle a three-dimensional depth filter that is characterized by the presence of adsorbents, compounds with a large internal surface.

Hobrafilt® filter sheets of the “NT” series were especially developed for economic use during filtration in the beverage, chemical and pharmaceutical industries. The sheet thickness and composition were designed to remove impurities during filtration from a typical production batch so that the sheets have the filtration capacity required for the given filtration. This practically eliminates the unused capacity of sheets and increases efficiency. In case of a high concentration of impurities, we recommend consulting the use of Hobrafilt® filter sheets of the “NT” series with our specialists.

Documents to download:

Product leaflet HOBRAFILT - „NT“ Series (916.4KB, .PDF)

Applications:

Wine

Beer

Alcoholic beverages

Soft drinks

Food

Chemistry

Pharmacy

Oil and biofuel

Characteristic - Hobrafilt

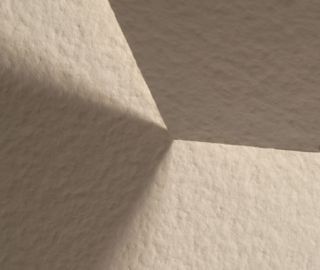

A filtersheet is essentially a three-dimensional, deep filter consisting of adsorbents of a large inner surface. This can be imagined as a labyrinth of little chambers and channels of different lengths inside the sheet where dirt is captured.

Contrary to screen filtration, the presence of adsorbents in a deep filtersheet will multiply the total filtration area and, thereby, increase the quantity of the solution being filtered.

Filtration mechanism

Three different filtration types as specified below are applied in the filtration process over filtersheets. In practice, normally, none of the three filtration mechanisms occurs separately during filtration due to the wide range of particle size but they are more or less combined, which is decisive for the filtration result.

- Mechanical filtration – direct filtration of foreign substances. All particles greater than the filtersheet holes are captured mechanically on its surface.

- Electrostatic adsorption – light molecular interactions, Van der Waals forces, occurring among the particles of solutions and the filtersheet material and ensuring that particles smaller than the dimensions of the sheet's inner pores are captured in the little chambers and channels of the filtersheet.

- Electrokinetic adsorption – this is based on the existence of Zeta potential and is applied in microbiologically effective sheets. Excellent filtration/separation effects towards negatively charged particles of dirt, microorganisms and viruses suspended in the liquid being filtered are achieved through the change of the naturally negative electrokinetic charge of the filtersheet to positive - i.e. Zeta potential. This is achieved by a special treatment with polyelectrolytes that are not harmful to health. This treatment makes it possible to capture particles up to ten times smaller than the dimensions of the filtersheet pores.

HOBRAFILT filter sheets are delivered in the format 20x20, 40x40 and 60x61,4 cm. Based on customer requirements are also supplied other dimensions, such as circular or sheets with various holes, etc.

Documents to download:

HOBRAFILT - Conditions for successful filtration (900.6KB, .PDF)

HOBRAFILT - Product sheet (831.1KB, .PDF)

HOBRAFILT – selected high-flow filter sheets for specific applications (856.1KB, .PDF)