„Effective Heat and Temperature Control“ is HOBRA’s comprehensive mark, under which all the company’s products and services in refractory and insulation applications are identified. In essence, it is a marketing project which covers everything HOBRA manufactures, offers and supplies in these spheres.

Efective heat and temperature control

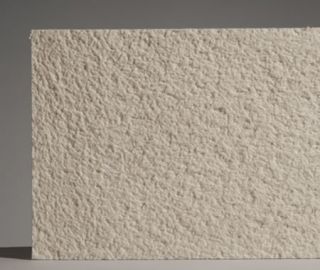

SIBREX® 300

The solid refractory SIBREX® 300 boards are produced using paper-making technology, are made of aqueous suspension composed of fibrillated ceramic aluminosilicate fibers (previously also known as Sibral), and of combined bonding agents and other additions.

Thanks to the innovative combination of inorganic and organic bonding agents, the plates have excellent mechanical properties with heat-resistance up to 1100°C. The boards do not contain asbestos and are therefore suitable for asbestos-plate replacement. They can easily be used in all sorts of applications (e.g. high-temperature insulation and sealing). The boards are a very good construction material for the insulation of high-temperature aggregates in combination with heat-proof bricks, or heat-resistant concrete, where they work as an insulating and dividing layer of the outer coat. The material can deal with very high static load, and is easily workable (while work safety standards are kept). The boards can also be put up together with heat-resistant sealant and used on already existing ceramic walling such as those found in industrial furnaces.

SIBREX® 300 boards are manufactured using the paper-processing technology from a water suspension consisting of loose aliminosilicate fibres, combined binders and admixtures.

SIBREX® 300 boards are used in the following applications, but are not limited to them:

- Metallurgy

- Insulation and repairs of all furnace types

- Expansion insulation behind brick (concrete) masonry

- Insulation of ladle and furnace lids

- Insulation of mixers, heaters, etc.

- Boiler production

- Insulation of doors and exhausts

- Brick industry

- Insulation and sealing of furnace cars

- Expansion components of furnace insulation

- Other

- Insulation of heating furnaces and parts of glass tanks

- High-temperature sealing for all applications

- Fire and heat radiation protection

- Metallurgy of ferrous and non-ferrous metals

- Fire-resistant doors

More detailed information about this product, including technical data, can be found in the downloadable documents below.

Documents to download:

SIBREX® (249.8KB, .PDF)

Applications:

Metallurgy and foundry

Engineering

Glass and Ceramics

Civil Engineering